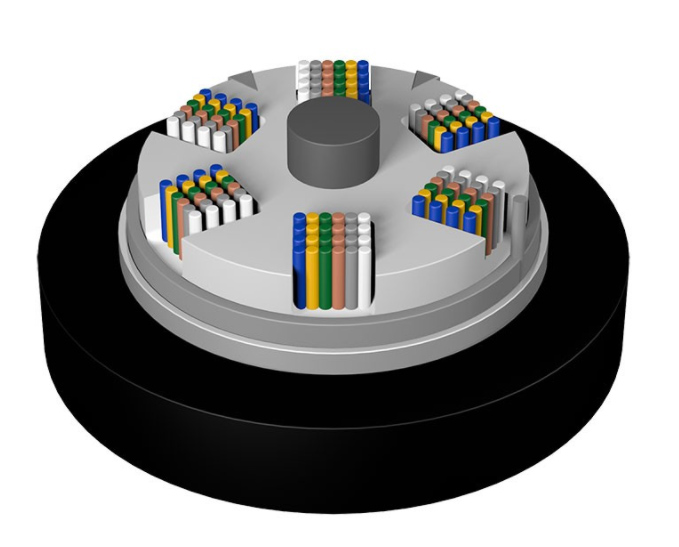

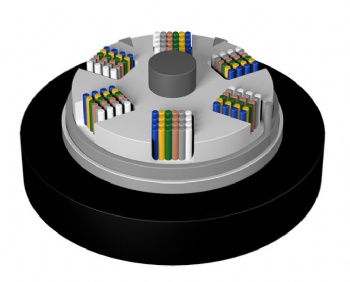

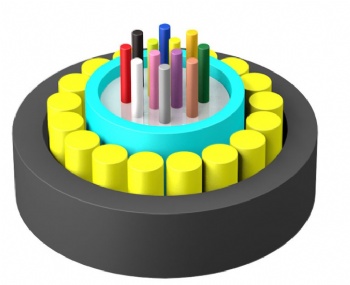

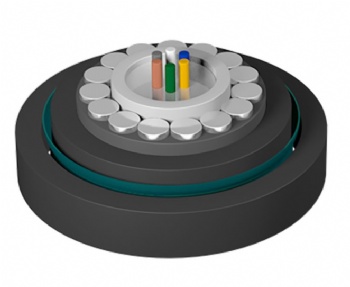

Skeleton fiber optic cable with A sheath (GYDGA)

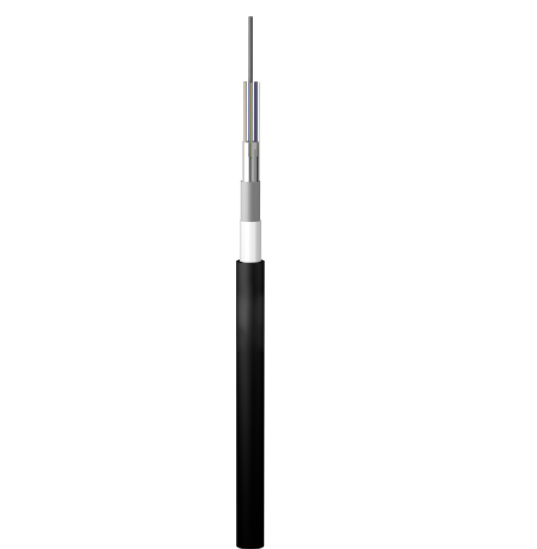

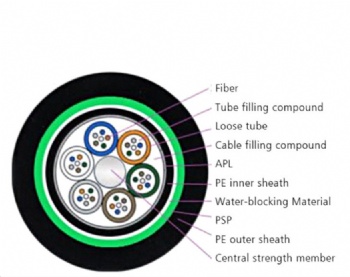

The structure of the GYDGA cable is as follows: the fiber ribbon is placed in the groove of the skeleton made of high density polyethylene (HDPE), and the center of the skeleton is a single steel wire or multi-stranded steel wire. A layer of waterstop tape is wrapped around the framework, and the double-sided plastic-coated aluminum tape (APL) is longitudinally wrapped, and then the polyethylene (PE) sheath is extruded. Place a tear cord between the strip and the waterstop to facilitate sheath stripping.

The product application

GYDGA fiber optic cable has the advantages of high fiber assembly density, good side pressure resistance, and high connection efficiency, which fully meets the requirements of modern communication development (such as FTTB, FTTH, etc.) for construction and communication capability, especially suitable for relay network and access network.

Product features

• Good structural design and process control, with superior optical, mechanical and environmental performance

• The use of fast and high expansion rate waterproof belt, fully ensure the optical cable water resistance performance

• All-dry water-blocking structure without fiber paste and cable paste, which overcomes the disadvantage of traditional oil paste that is not easy to remove, reduces construction preparation time, greatly improves the connection efficiency, and facilitates construction and maintenance

• Skeleton structure has good lateral compression resistance and good protection for optical fibers

• High fiber assembly density, small diameter, light weight, easy laying

• After the skeleton structure is peeled, the optical fiber tape can be taken out directly for easy divergence

• The tearing rope is placed in the jacket for easy peeling

Categories

Contact Us

- +86-0558 8538081

- +86-0558 8538081

- +86-13530061893

- lyd@ahflylink.com

- Skype

- +86-13530061893

售前客服

售前客服