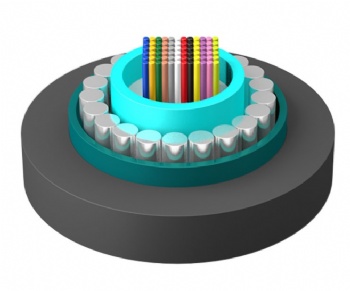

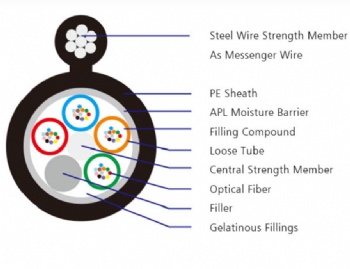

Center tube S-sheathed optical fiber with anti-rat cable (GYDXTS)

The structure of GYDXTS optical cable is to insert multiple optical fiber strips into a loose sleeve made of high modulus polyester material, which is filled with waterproof compound. The loose sleeve is provided with water-blocking material to ensure the longitudinal water seepage of the optical cable. After the steel wire is wrapped into cable, the steel wire is wrapped longitudinally with double-sided chromium-plated plastic-coated steel strip (PSP), and then the polyethylene sheath is extruded outside.

YD/T 769-2010 and IEC 60794-1 standards.

Product features

• Precisely controlled optical fiber residual length ensures good mechanical and temperature performance of the cable

• The loose casing material itself has good hydrolysis resistance and high strength

• The tube is filled with special ointment, providing critical protection to the optical fiber

• Good lateral compression resistance and flexibility

• A layer of wrapped steel wire ensures the tensile strength of the cable, and has good anti-rodent performance

• Dual chrome-plated plastic steel belt (PSP) improves cable moisture resistance

• Good water-blocking material to prevent longitudinal water seepage of optical cable

• Polyethylene (PE) sheath provides excellent uv resistance

• Small diameter, easy to lay

Categories

Contact Us

- +86-0558 8538081

- +86-0558 8538081

- +86-13530061893

- lyd@ahflylink.com

- Skype

- +86-13530061893

售前客服

售前客服