Non-metallic Flame Retardant Optical Cable (MGTS53) for Loose Layer Stranded Coal Mine

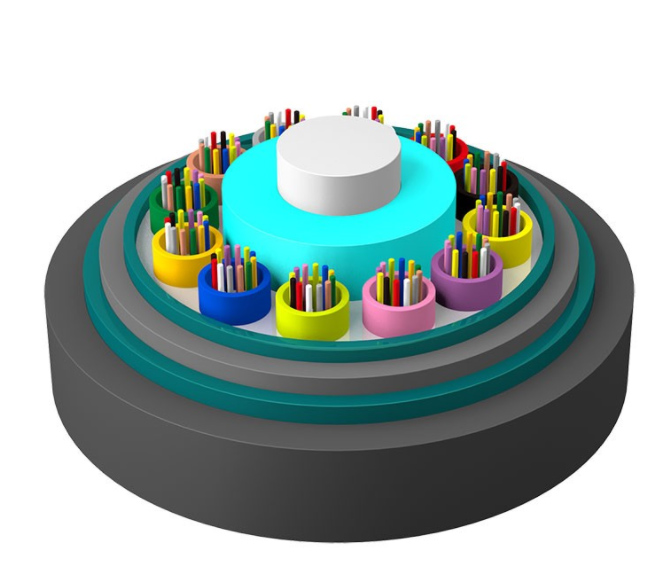

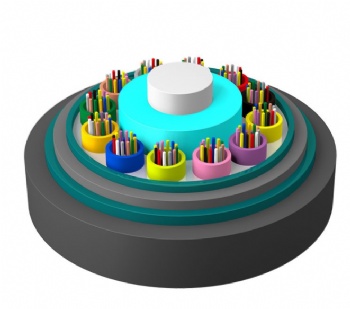

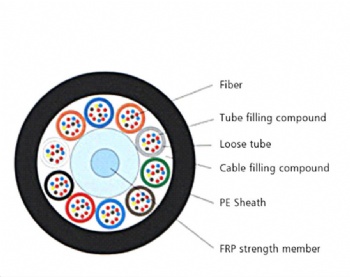

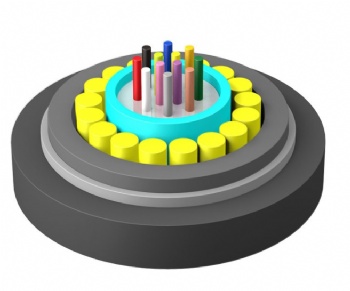

The structure of MGTS 53 optical cable is that 250 µ m optical fiber is sheathed in a loose sleeve made of high modulus material, and the loose sleeve is filled with waterproof compound. The center of the cable core is a metal reinforced core, and for some number of optical cables, the metal reinforced core needs to be squeezed with a layer of polyethylene (PE). The loose sleeve (and packing rope) is twisted around the central reinforcing core to form a compact and circular cable core, with gaps in the cable core filled with water blocking filler. The inner cable core is formed by extruding polyethylene sheath after longitudinal wrapping of double-sided plastic-coated steel strip (PSP). Then protect a layer of double-sided plastic coated steel strip (PSP) sheath into cable. There are water blocking materials between the inner and outer sheaths. Wrap a layer of flame retardant sheath into cable.

Product standards

MGTS cable conforms to YD/T 901 and MT386 standards. MA certified.

Product features

• Good mechanical properties and temperature characteristics

• The loose casing itself has good hydrolysis resistance and high strength

• The tube is filled with special ointment, providing critical protection to the optical fiber

• Specially designed tight cable structure to prevent casing retraction

• Good compression resistance and flexibility

• Double sheath for enhanced lateral pressure resistance

• Flame retardant steel belt sheath has intentional flame retardant properties

• Use the following measures to ensure the cable waterproof performance:

- Single non-metallic central strengthening core

- The loose casing is filled with a special waterproof compound

- Complete cable core filling

- Two sides coated plastic steel belt (PSP) improves cable moisture resistance

Categories

Contact Us

- +86-0558 8538081

- +86-0558 8538081

- +86-13530061893

- lyd@ahflylink.com

- Skype

- +86-13530061893

售前客服

售前客服