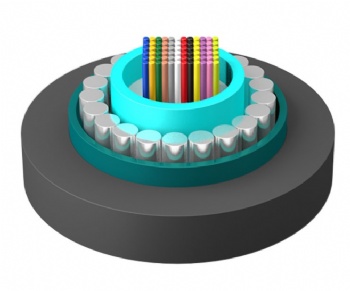

Detection optical cable for coal mine (MGJS)

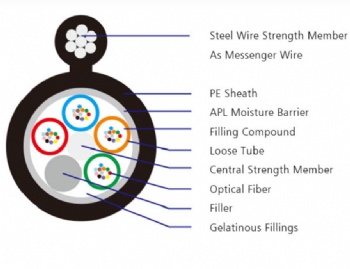

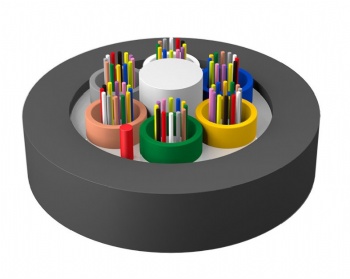

The monitoring optical cable for coal mine uses the Φ 600 µ m flame-retardant tightly-sheathed optical fiber as the optical transmission medium, and uses the stainless steel hose to enhance the anti-torsion performance of the optical cable. It is covered with a layer of aramid fiber as the force strengthening unit and extruded with a layer of low-smoke halogen-free material (LSZH, low-smoke, halogen-free, flame-retardant) sheath.

Product application

· Fiber-optic active connection jumpers or pigtails

· Indoor wiring

Product standard

Meet YD/T 1258.2-2003, ICEA-596, GR-409, IEC 60794-2-10/11 and other standards; pass coal safety certification.

Product Features

· Tight-sleeve optical fiber for easy stripping

· Tight sheathed optical fiber has good flame retardant performance

· Aramid reinforcement element for excellent tensile properties of optical cable

· Anti-corrosion, waterproof, anti-UV, flame retardant, environmental protection and other advantages of external protective materials

· Stainless steel hose reinforcement element for excellent compression performance of optical cable

· Precise processing technology and scientific and reasonable design

Categories

Contact Us

- +86-0558 8538081

- +86-0558 8538081

- +86-13530061893

- lyd@ahflylink.com

- Skype

- +86-13530061893

售前客服

售前客服