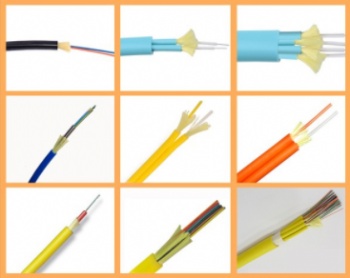

All types of outdoor optical cable customized

Detailed introduction

The product description

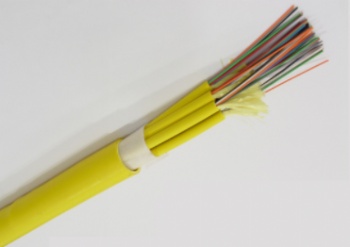

The fibers, 250μm, are positioned in a loose tube made of a high modulus material. The tubes are filled with a waterproof compound. At the center of the cable core is a metal reinforcing core. For some cables with a certain number of cores, a layer of polyethylene (PE) is added to the metal reinforcing core. The loose tube (and filler) is twisted around the central reinforcement core to form a compact and round cable core. The gaps in the cable core are filled with water-blocking filler. The cable is longitudinally coated with PSP and then squeezed with PE sheath.

· Product features · Excellent mechanical properties and temperature characteristics · The loose tube material itself has good water resistance and high strength · The pipe is filled with special oil to provide critical protection for the optical fiber · Specially designed tight structure of the cable Effective prevention of casing retraction · Good compressive resistance and flexibility · PE sheath has good uv radiation resistance · The following measures are adopted to ensure the waterproof performance of the cable: - single wire center to strengthen core - pine casing fill special waterproofing compound - completely fill - cable core Double-sided plastic-coated steel strip (PSP) improves moisture permeability of fiber optic cables. Product Standard GYTS fiber optic cables comply with YD/T 901-2001 and IEC 60794-1 standards

G. 652, g. 655 50/125 62.5/125 mu mu m m

Attenuation (+20℃) @850nm ≤ 3.0dB /km ≤ 3.0dB /km

@1300nm ≤ 1.0db /km ≤ 1.0db /km

@1310nm ≤ 0.36db /km ≤ 0.40db /km

@ 1550 nm 0.22 dB/km or less 0.23 dB/km or less

Bandwidth (class A) @850nm ≥500 MHz·km ≥200 MHz·km

@1300nm ≥ 1000mhz ·km ≥ 600mhz ·km

Numerical aperture 0.200± 0.015Na 0.275± 0.015Na

Optical cable cutoff wavelength ≤1260nm ≤1480nm

· Structural parameters

Optical cable type number of optical fibers number of tubes number of filling ropes diameter mm weight kg/km allowable tensile force long-term/short-term Term N allowable flattening force long-term/short-term N/100mm bending radius static/dynamic mm

Gyts-2 ~6 core 2~6 1 4 10.2 116 600/1500 300/1000 10D/20D

Gyts-8 ~12 core 8~12 2 3 10.2 116 600/1500 300/1000 10D/20D

Gts-14 ~18 core 14~18 3 2 10.2 116 600/1500 300/1000 10D/20D

Gyts-20 ~24 core 20~24 4 1 10.2 116 600/1500 300/1000 10D/20D

Gts-26 ~30 core 26~30 50 10.2 116 600/1500 300/1000 10D/20D

Gts-32 ~36 core 32~36 60 0 10.6 129 1000/3000 300/1000 10D/20D

Gts-38 ~48 core 38~48 41 11.2 141 1000/3000 300/1000 10D/20D

Gyts-50 ~60 core 50~60 50 0 11.2 141 1000/3000 300/1000 10D/20D

Gts-62 ~72 core 62~72 60 0 12.0 159 1000/3000 300/1000 10D/20D

Gts-74 ~84 core 74~84 7 1 13.6 209 1000/3000 300/1000 10D/20D

Gts-86 ~96 core 86~96 80 0 13.6 209 1000/3000 300/1000 10D/20D

Gts-98 ~108 core 98~108 9 1 15.4 232 1000/3000 300/1000 10D/20D

Gts-110 ~120 core 110~120 100 15.4 232 1000/3000 300/1000 10D/20D

Gyts-122 ~132 Core 122~132 11 1 17.2 280 1000/3000 300/1000 10D/20D

Gts-134 ~144 core 134~144 12 0 17.2 280 1000/3000 300/1000 10D/20D

Storage and service temperature: -40℃ to + 70℃

Categories

Contact Us

- +86-0558 8538081

- +86-0558 8538081

- +86-13530061893

- lyd@ahflylink.com

- Skype

- +86-13530061893

售前客服

售前客服