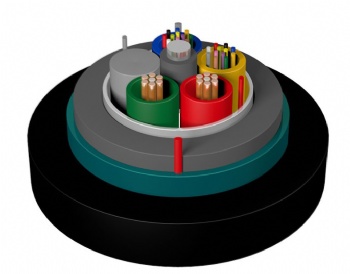

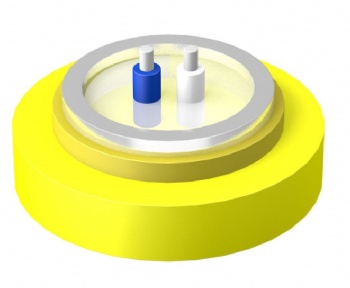

Opto-electronic hybrid cable for access network (GDTA53)

For cables, a layer of polyethylene shall be extruded outside the metal reinforced core. Loose sleeves and insulated copper conductors of the required size are twisted around the central reinforcing core to form a compact round core, with gaps in the core filled with water blocking filler. A layer of polyethylene inner sheath is extruded after longitudinal wrapping of plastic-coated aluminum strip, and the outer surface of double-sided chrome-plated plastic-coated steel strip (PSP) is rolled and longitudinally wrapped and then extruded into a cable.

Product Features

· Optoelectronic integration to solve equipment power consumption and signal transmission problems, and provide centralized monitoring and maintenance of equipment power supply

· Improve power manageability and reduce power coordination and maintenance

· Reduce procurement costs and save construction costs

· Accurately controlled fiber redundancy ensures good tensile and temperature characteristics of the cable

• Is mainly used in distributed base station DC remote supply system to connect BBU and RRU

· Suitable for directly buried laying

Delivery length

Recommended length: 2000m; other lengths available upon request

Environmental characteristics

Transportation/storage/service temperature: -40℃ ~ + 70℃

Categories

Contact Us

- +86-0558 8538081

- +86-0558 8538081

- +86-13530061893

- lyd@ahflylink.com

- Skype

- +86-13530061893

售前客服

售前客服